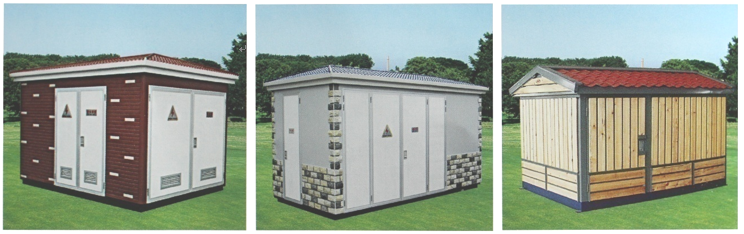

Prefabricated substation

The prefabricated substation is an economical, fast, safe and reliable power distribution device in today's power distribution system. It is a pre-installed mobile power distribution device integrating high-voltage switchgear, transformer and low-voltage switchgear.

The prefabricated substation has strong set, small size, small footprint, deep load center, improved power supply quality, reduced line loss, shortened power transmission cycle, flexible site selection, strong environmental adaptability, convenient installation, safe and reliable operation. A series of advantages such as less investment and quick results. It can be widely applied to urban public power distribution, high-rise buildings, residential quarters, parks, highways, etc. It is also applicable to oil fields, industrial and mining enterprises and temporary construction sites.

Our company adheres to the tenet of contributing to the country and serving the society. After years of hard work and continuous improvement. It has produced prefabricated box-type substations that meet the requirements of China's power distribution characteristics and technical standards, and passed the type test of national authorities. It has high technology content and can be coordinated according to user requirements and environment, and has a good landscape effect. The product complies with GB/T17467 "High Voltage / Low Voltage Prefabricated Substation", DL/T537 "6~35kV Box Substation Ordering Technical Conditions" and other standards.

Conditions of Use

★ The altitude does not exceed 2000 meters;

★ The ambient temperature does not exceed +40 ° C, not lower than -25 ° C;

★ Non-conductive dust, no corrosive gas, no explosion hazard;

★ The outdoor wind speed does not exceed 35m/s;

★ Relative humidity does not exceed 90% (+25 °C);

★ There is no violent vibration and bumps in the installation place, and the vertical slope does not exceed 5°;

★ The seismicity is not more than 8 degrees;

★ Special use conditions (such as wet tropics, highland areas) are negotiated with the company.

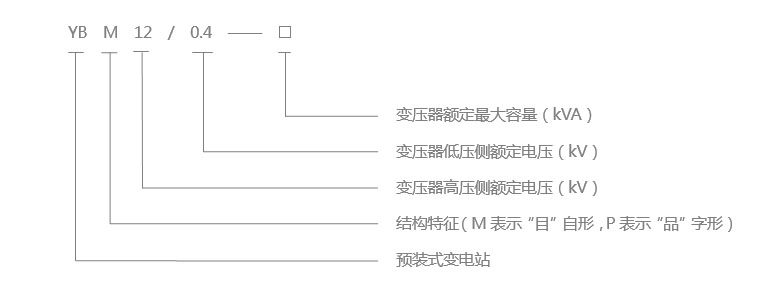

Model Description

Structural features

★ The bottom frame of the box is made of steel and is specially treated with anti-corrosion treatment. The specification of the steel is selected according to the size of the box and the capacity of the transformer. There are sunken base and oil groove base for users to choose. The inside of the box is divided into high-voltage switch room, transformer room and low-voltage switch room by metal steel plate, and each room is strictly isolated. The structure layout is divided into “product” shape, “mesh” shape, and internal operation and external operation; the whole box is divided into “single transformer configuration” and “dual transformer configuration”; high voltage switch “terminal” power supply and “ring network” "Power supply, etc.; once equipped with "cable type" and "mother row type"; electric metering secondary instrument system has built-in and external type. Each room is equipped with lighting and is equipped with a lock switch and forced ventilation. Each structure and device requirements can be selected from the company depending on the user;

★ Push-pull lifting device is installed on both sides of the bottom of the box, which is convenient for lifting, transportation and installation. There are total grounding device points around the bottom frame, which can be selected by the user.

★ The high and low voltage switch room can adopt standard type structure, and can also adopt screen type and frame type structure. The former is strong in complete set, and the whole machine is compact and compact.

★ The transformer can be either oil-immersed or dry. The former is bulky and cheap; the latter is small in size and reliable, does not cause combustion and explosion, and can be used in a variety of environments.